Wood Hammer Mill Sawdust Machine Garden Waste Wood Tree Branch Chipper Shredder Crusher Machine

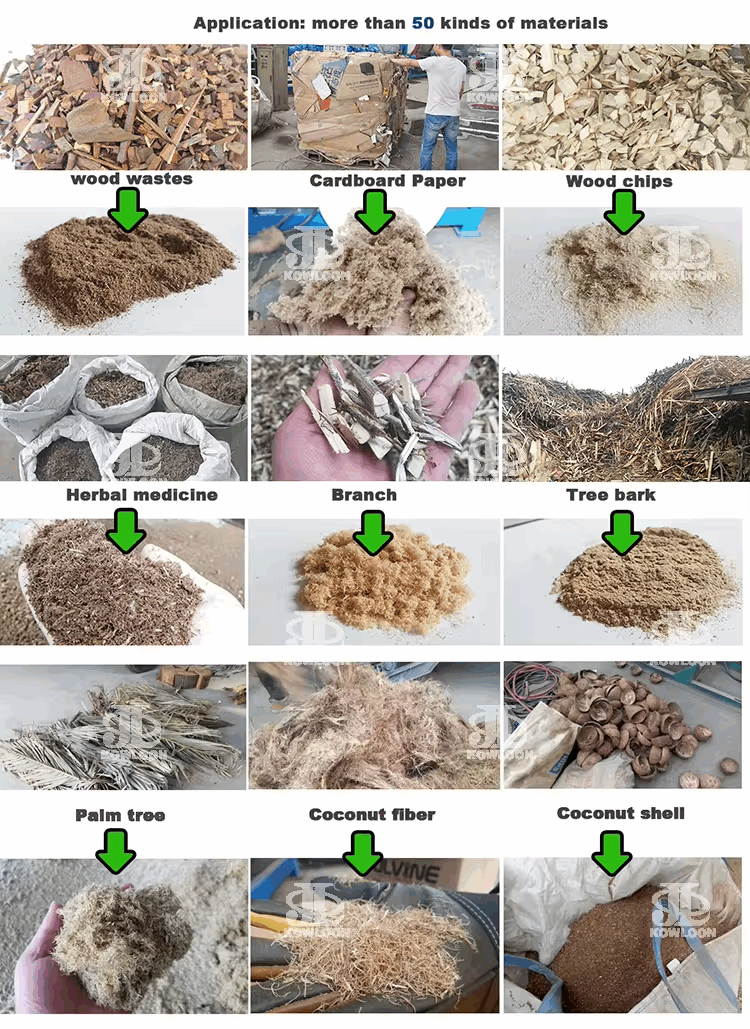

Application Material:

Bark, leaves, wet branches, wooden strips, coconut shells, rice husks, wooden cases, wood chips, wooden trays, waste boards, logs, corn cobs, bamboo, Chinese medicinal materials, straw, sugarcane leaves, corn stalks, etc.

Power:75-300KW

- Fitted Solution and Offer , 24 Hours Online.

- Oversea Installation , Training on Request .

- Continue provide Wearing Parts and Service !

Video

Description

Wood Hammer Mill Sawdust Machine Garden Waste Wood Tree Branch Chipper Shredder Crusher Machine

JLSD hammer grinder application: maximum 300x300mm wood chips, bamboo chips, cotton stem chips, cardboard shreds, white paper shreds, textile shred and other fabric waste pieces. These raw materials can be grinded into 20x20mm and smaller particles, these granules or particles widely used as basic raw material of making paper, particleboard, fiberboard, non wood-based board and pulping and papermaking.

Features

1.JLSD1500 wood hammer mill grinder equipped two 55kw/75kw motors to drive single rotor.

2.Enclosed design, equipped with pulse dust collector and discharge by enclosed screw conveyor, ensure working in low dust condition, workable inside workshop.

3.High rotary speed, is able to process fabric into fiber, process cardboard into paper fiber, process wood chips into sawdust...etc

4.Screen mesh size is customized for different requirements on size of end product.

5.Grinding room is open able by hydraulic, ease to maintenance and hammers replacement.

JLSD hammer grinder application: maximum 300x300mm wood chips, bamboo chips, cotton stem chips, cardboard shreds, white paper shreds, textile shred and other fabric waste pieces. These raw materials can be grinded into 20x20mm and smaller particles, these granules or particles widely used as basic raw material of making paper, particleboard, fiberboard, non wood-based board and pulping and papermaking .

This wood sawdust machine is suitable for crushing bark, leaves, wet branches, wood strips, coconut shells, rice husks, wooden boxes, wood chips, wooden pallets, waste boards, logs and other materials, and the output particle size is adjustable. This machine is suitable for special auxiliary equipment for industrial production such as power plants, furniture factories, wood-based panel processing plants, biomass fuels, edible fungus planting, fertilizers, papermaking, granulation, mechanism charcoal, and particle boards.

The wood sawdust machine will generate a part of the air volume while crushing, and the method of using a negative pressure fan will make the air volume even more difficult to handle. As long as there is wind, there will be dust, and the greater the wind force, the more difficult it is to handle. Because the diameter of the grinder is too long, we choose two 55KW motors to rotate a large shaft together, which makes good use of the strength of the motor to drive the wood grinder, which is also a design highlight for increasing production.

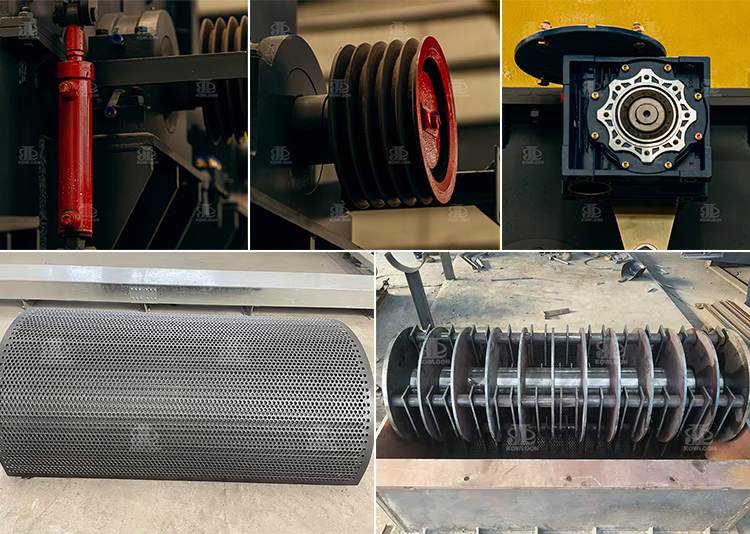

The wood sawdust machine is a new type of ideal woodworking machinery for the production of wood series. Wood shredder components are mainly composed of organic casing, bearings, screens, transmission wheels, and grooved frames, and all materials are cast from manganese steel.

Features:

- Enclosed design, equipped with pulse dust collector and discharge by enclosed screw conveyor, ensure working in low dust condition, workable inside workshop

- High rotary speed, is able to process fabric into fiber, process cardboard into paper fiber, process wood chips into sawdust...etc

- Screen mesh size is customized for different requirements on size of end product.

- Grinding room is open able by hydraulic, ease to maintenance and hammers replacement

The wood sawdust machine is composed of three parts: the body, the middle body and the lower body. The middle body is equipped with a triple stator ring, a crushing cutter head and a fineness analyzer. The host of the wood shredder adopts alloy cutter head, which has coarse crushing, fine crushing, and centrifugal crushing. The motor drives the shredder rotor to run at high speed, so that the machine generates high-speed airflow to generate high-intensity impact force, compression force, and cutting force on the crushed materials. , and achieve the crushing function.

With years of technical experience, Kowloon Machinery has independently developed a dust-free wood shredder. Compared with traditional wood shredding equipment, this equipment is more in line with modern standards. The output fineness of this equipment can be adjusted, the working noise is small, and there is no dust pollution. , The effect of the finished sawdust is good, and the efficiency is increased by more than 50% compared with the traditional wood crusher.

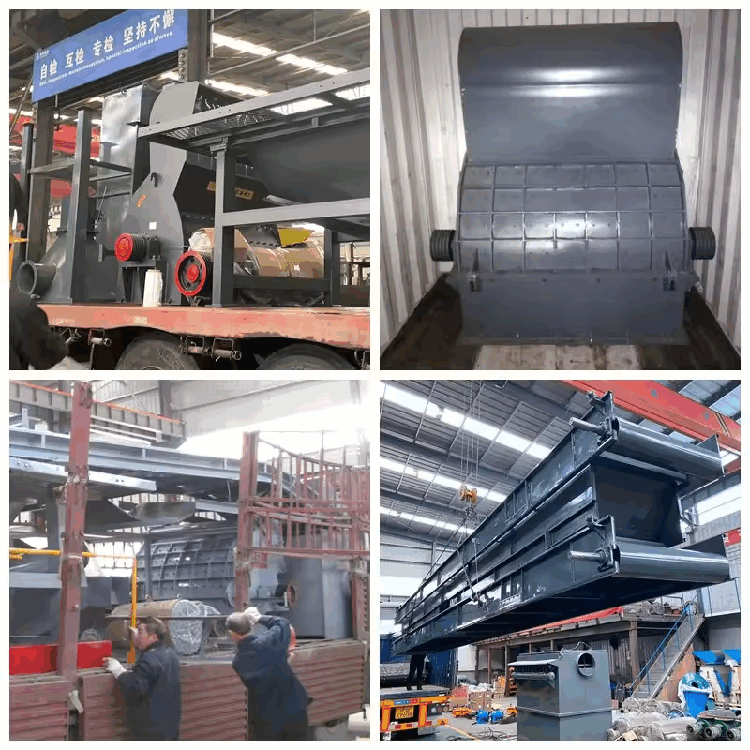

Delivery &Shipping for hammer mill

1.Plastic wraps to protect hammer mill from dust, moisture and corrosion.

2.Wooden case for compact machine or wearing parts as the outside package. Or according to the customer requirements.

3.Excellant logistic team to guarantee the shredder machines to be safely shipped to customer warehouse, no extra fee on export or import on custom.

The wood sawdust machine is mainly used for processing pine wood, miscellaneous wood, poplar wood, fir wood, raw bamboo and other materials, and is more suitable for wood chip processing in edible fungus culture medium. At the same time, the scrap crusher can also be used for cutting chips of fibrous stalk-like materials such as bamboo, thatch, corn stalks, and sorghum stalks. It can process all kinds of branches, slats, small-diameter center wood, leftovers, wood chips, moso bamboo, cotton stalks, and other materials into sawdust and wood filament products at one time, with low investment, low energy consumption and high productivity. , good economic benefits, easy maintenance and other advantages.

Kowloon Service

1. Pre-sales: Provide fitted solution and offer to customers, is able to adjust the layout of complete line to fit customers working area, also provide technical support 24 hours service online.

2. After sales:

Kowloon skilled technicians are experienced at oversea installation, therefore they are available to assist with onsite installation, commissioning & training on request. Layout drawing, circuit diagram and maintenance manual will be provided together with our products after sales, so that ensure customers have plenty of time to get prepared for installation.

3. Wearing parts support

Kowloon has widely built extensive cooperation with wearing parts partner manufacturers more than 14years, has ability to continuously provide wearing parts and after-sale service to global market.

Kowloon has widely built extensive cooperation with wearing parts partner manufacturers more than 14years, has ability to continuously provide wearing parts and after-sale service to global market.

Company Introduction

Kowloon Machinery located in industrial hub of Zhengzhou city, China, design and manufacture industrial shredder, wood processing machinery, waste tire recycle equipment and scrap metal recycling machines. Kowloon products approved by CE and ISO certificates. Up to now, we have exported to more than 30 countries and share markets in worldwide, and now are still growing continuously.

We effort on improving and researching, in past years, various of new products were developed and becomes popular in domestic and abroad market, won good reputation and corporate image, we always effort on best quality and service, welcome to inquiry!

Technical Data

|

Model |

JLSD1500 |

|

|

Infeed port size |

1468*450mm |

|

|

Hammer blade |

66pcs, made of 65Mn |

|

|

Liner plate |

M13Cr2, 42pcs |

|

|

Output material size |

3-30mm (screen customizable) |

|

|

Main motor |

75kw+75kw |

|

|

Discharging conveyor motor |

11kw |

|

|

Feeding conveyor motor |

4kw |

|

|

Hydraulic motor |

2.2kw |

|

|

Output screw conveyor |

Dia.273mm x 1, motor 7.5kwx1 |

|

|

Dust collector |

48-bag pulse dust collector,4kw |

|

|

Cyclone |

With air-lock valve, fan 7.5kw |

|

|

Dimension |

3150*3250*3350mm |

|

|

Weight |

5500kg |

Clients