Tire Recycling Plant Line Waste Rubber Tyre Crusher Recycling Shredder Crusher System

Applicable Materials:

Bicycle tires, Electric vehicle tires, Motorcycle tires, Passenger car tires, Bus tires, Off-road vehicle tires, Agricultural and Forestry machinery tires, Light truck tires, Construction machinery tires, Industrial vehicle tires.

Power :55-110 KW Production :1-3 Tons/Hour

- Fitted Solution and Offer , 24 Hours Online.

- Oversea Installation , Training on Request .

- Continue provide Wearing Parts and Service !

Video

Description

Rubber Tire Recycling Plant Line Waste Tyre Crusher Recycling Shredder Crusher System

Low speed, high torque rotor, cutting and shearing working principle suitable for both soft and hard materials;

Blades made of special alloy, different shape, thickness and cutting head quantity providing the optimum solution for different materials.

Siemens, ABB, WEG-etc quality motors are available for different customers options

Schneider, Chint, Siemens¡-etc electrical components to ensure steady performance and realize machine 24hours running, also PLC system is optional to enabling automatic reverse for overload protection and minimizing blades damages;

Individual electrical control panel with PLC control system ensure the machine work properly

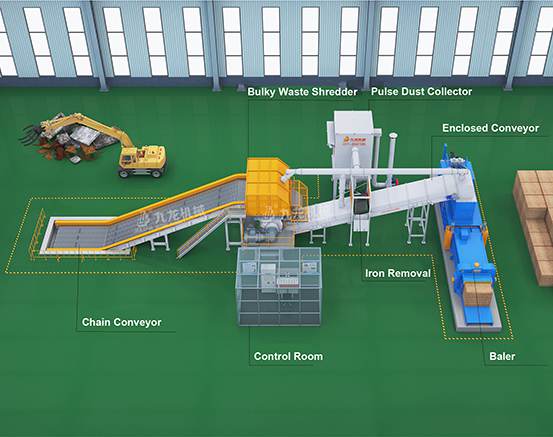

Kowloon industrial shredder is sort of twin shaft shredding machine, widely used for household garbage, municipal solid wastes, scrap metal recycling and waste rubber like car and truck tires downsize, also apply to size reduction of IBC tank, plastic/metal barrel, waste furniture, sofa, mattress, home appliances and other large size materials, which inconvenient for transportation, the shreds after processing can also be used for secondary resources recovery .

Low speed, lower noise, workable in workshop and outdoor .

Tire Shredders & Recycling Equipment

Kowloon Machinery offers a complete line of tire shredders and recycling equipment designed to process scrap tires for recycling and repurposing for a variety of applications.

Scrap Tire Shredding Solutions

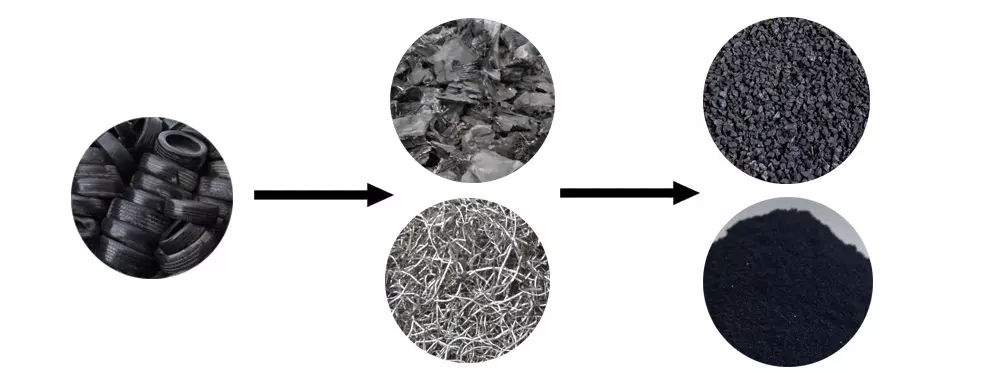

Ourt line of tire shredders and recycling equipment includes a wide range of custom shredders, grinders and granulators, Excelling in efficiency, durability, and reliability, our equipment can process tires to generate clean rubber crumb, and the finest, cleane producst powder rubber for use in a variety of applications including:Bicycle tires, Electric vehicle tires, Motorcycle tires, Passenger car tires, Bus tires, Off-road vehicle tires, Agricultural and Forestry machinery tires, Light truck tires, Construction machinery tires, Industrial vehicle tires.

Used Tire Rasper Secondary Rubber Shredder Rubber Granulator Machine to Remove Steel

Kowloon Machinery JLRS granulator machine, designed to process maximum 300x300mm plastic or rubber pieces into 10-15mm granules, sometimes rubber or plastic composted with steel wires, JLRS granulator equipped with claw blade with teeth, is able to squeeze steel wires off and separate them via magnet separator above discharge conveyor, steel wire separating purity 98%.

Application

Waste tire shreds, steel composited rubber seal, natural gas pipeline shreds, scrap cables…etc

Features

1. Frequency conversion control, automatic stop feeding when overload.

2. Double-edged blades, each blade could be used twice3. Blades made of H13, high hardness, anti-wear , longer working life.

3. Hydraulic assistant system for helping open and changing screen and blade maintenance.

4. With pulse dust collector and enclosed feed hopper, low dust when work inside room.

Rubber Granulator In Rubber Recycling

1. Hydrualic system of the shredder to assist disassemble with the chamber open .

2. high output of the machinery . screw conveyor outcomes of the materials

3. the crusher sieve is take the carton steel thickness and strong

For rubber processing, rubber granulator is specially designed for rubber granulation process. The final product from the granulation process is much smaller than the product from the rubber crushing process.

Therefore, it is usually the third stop in the tire recycling line. After the tire granulation process, the final product is usually rubber pieces without fiber and wire. The first and second shredders were able to shred the tyres into 20mm pieces of rubber, and then the granulator could further grind them into 5mm particles. Of course, the size required can be adjusted, as there are different sizes of screens available to ensure more flexible production.

Features:

Low speed, high torque rotor, cutting and shearing working principle suitable for both soft and hard materials;

Blades made of special alloy, different shape, thickness and cutting head quantity providing the optimum solution for different materials.

Siemens, ABB, WEG -etc quality motors are available for different customers options

Schneider, Chint, Siemens¡-etc electrical components to ensure steady performance and realize machine 24hours running, also PLC system is optional to enabling automatic reverse for overload protection and minimizing blades damages;

Individual electrical control panel with PLC control system ensure the machine work properly and safety;

Detachable type cutting head on shredder blades, makes the maintenance and replacement of wearing parts easier and much shorten maintenance time.

Kowloon Service

1. Pre-sales: Provide fitted solution and offer to customers, is able to adjust the layout of complete line to fit customers working area, also provide technical support 24 hours service online.

2. After sales:Kowloon skilled technicians are experienced at oversea installation, therefore they are available to assist with onsite installation, commissioning & training on request. Layout drawing, circuit diagram and maintenance manual will be provided together with our products after sales, so that ensure customers have plenty of time to get prepared for installation.

3. Wearing parts support:Kowloon has widely built extensive cooperation with wearing parts partner manufacturers more than 14years, has ability to continuously provide wearing parts and after-sale service to global market.

Technical Data

Tire Shredders & Recycling Equipment

|

Model |

JLTS1200D |

JLTS1500D |

JLTS2000D |

JLTS2600D |

|

Main motor |

45kw+45kw |

55kw+55kw |

75kw+75kw |

90kw+90kw/110kw+110kw |

|

Motor brand |

WN/Siemens/ABB/WEG |

|||

|

Gearbox |

2units, planetary type, motor direct connected, gear driven |

|||

|

Rotor speed |

8-12rpm |

8-12rpm |

6-8rpm |

6-8rpm |

|

Shredder chamber size (inner) |

1115*1010mm |

1480*1050mm |

1920*1250mm |

2520*1450mm |

|

Shredder blade |

Dia.530mm |

Dia.530/560/600mm |

Dia.560/600mm |

Dia.720mm/900mm |

|

Screen hole size |

Dia.50mm-200mm |

|||

|

Lubrication system |

With automatic oil lubricator |

|||

|

Dimension |

3.2x2x1.9m |

4x1.7x2.4m |

5.5x3.5x3m |

6.2x4.3x3.3m |

|

Weight |

16500kg |

18000-22000kg |

25000-28000kg |

32000-34000kg |

|

Model

|

JLRS800

|

JLRS1000

|

JLRS1200

|

JLRS1500

|

|

Main motor

|

55kw

|

75kw

|

90kw

|

110kw

|

|

Rotor diameter

|

460mm

|

460mm

|

670mm

|

670mm

|

|

Moving blade

|

36pcs, H13K

|

42pcs, H13K

|

36pcs, H13K

|

48pcs, H13K

|

|

Bottom blade

|

12pcs, H13K

|

14pcs, H13K

|

12pcs, H13K

|

16pcs, H13K

|

|

Hydraulic open assistant

|

2.2kw

|

2.2kw

|

3kw

|

3kw

|

|

Self-discharge belt conveyor

|

2.2kw

|

2.2kw

|

2.2kw

|

3kw

|

|

Magnet separator

|

1.5kw

|

1.5kw

|

1.5kw

|

2.2kw

|

|

Dimensions

|

3.35*2.02*3.05m

|

3.5*2.02*3.05m

|

4.05*2.35*3.8m

|

4.55*2.45*3.8m

|

|

Model

|

JLSP800

|

JLSP1000

|

JLSP1200

|

JLSP1500

|

|

Main motor

|

55kw

|

75kw

|

90kw

|

110kw

|

|

Rotor diameter

|

600mm

|

600mm

|

700mm

|

700mm

|

|

blade

|

Made of H13, solid blade

|

|||

|

Hydraulic station

|

2.2kw

|

2.2kw

|

3kw

|

3kw

|

|

Self-discharge belt conveyor

|

2.2kw

|

2.2kw

|

3kw

|

3kw

|

|

Screen hole size

|

Dia.3-7mm

|

|||

|

Dimensions

|

3.35*1.65*2.95m

|

3.25*1.85*2.95m

|

2.7*2.05*3.45m

|

2.7*2.4*3.45m

|

Clients