Motorcycle Crusher Machine Scrap metal Motorcycle Crushing Equipment Multi purpose

Application Materials :Motorcycle frame, bicycle frame, color steel tile, carriage board, keel strip, etc.

Power :18.5-220 kw

Production :600-12000kg/h

Make full use of the theory of impact, shear, mutual impact, grinding, etc.

- Fitted Solution and Offer , 24 Hours Online.

- Oversea Installation , Training on Request .

- Continue provide Wearing Parts and Service !

Video

Description

Motorcycle Crusher

【product details】

The motorcycle crusher is an advanced fine crushing equipment, which is carefully developed on the basis of absorbing the advantages of various crushers and fully utilizing the theory of impact, shearing, mutual impact and grinding.

【Application Materials】

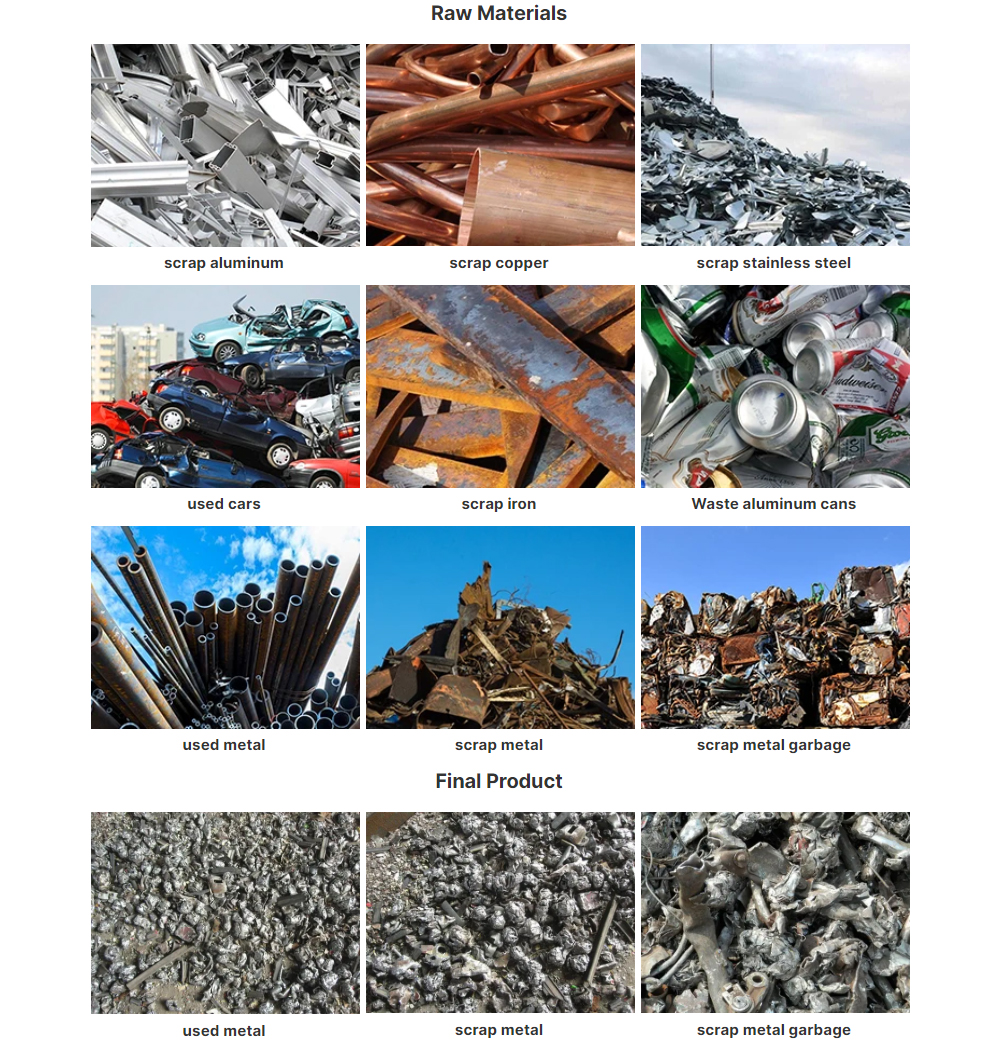

Bicycle frame, motorcycle frame, color steel tile, carriage board, keel strip, etc.

【Power】18.5-220kw

【Production】600-12000kg/h

Product Description

The motorcycle crusher is mainly composed of a car crusher, a production line, a magnetic separation device, a conveyor, and a motor. Never return material, will not cause harm.

When working, the material can be fully and effectively crushed in the crushing cavity, with high output, low energy consumption, high efficiency, and uniform discharge. It is mainly used for scrap metal crushing equipment such as bicycle frames, motorcycle frames, color steel tiles, carriage boards, keel bars and so on.

Applicable materials: bicycle frame, motorcycle frame, color steel tile, carriage board, keel strip, color TV, refrigerator, washing machine, scrap angle steel, scrap square tube, filing cabinet, safe, car slot, packing block, electrical shell, cans , beer cans, cans, Sprite cans, Lulu cans, paint buckets, bicycles, motorcycles, car shells, color steel tiles, scrap angle iron, rolling shutters, iron boxes, etc.

Prospects for development: As various major steel countries have issued decrees to restrict the export of steel, the supply of steel is very tight, which can be said to be a crisis in the steel industry. But the understanding of the word "crisis" should be excavated from another depth. "Crisis" is the coexistence of danger and opportunity. If you know where the opportunities are and how to seize them, you can open up a new future for yourself. Take the current scrap steel processing industry as an example, because of the shortage of steel, the price of scrap steel will rise. Generally speaking, in the next few years, motorcycle The development trend of the car crusher will be the coexistence of "crisis" and "opportunity".

working principle

The motorcycle crusher uses the basic principle of hammering. Driven by a high-speed and high-torque motor, the hammers on the rotor of the main engine take turns to hit the objects to be crushed that enter the cavity, and pass through the space formed between the lining plate and the hammer. , the material to be crushed can be fully and effectively crushed in the crushing cavity, and the material to be crushed can be torn into pieces that meet the specifications. There is a dust removal device, which reduces the harm of dust pollution in the production process. The equipment mainly has the advantages of high output, low energy consumption, high efficiency, and uniform discharge of finely divided materials. In addition, the equipment has low noise, low pollution and simple operation during use. , easy maintenance.

Performance characteristics

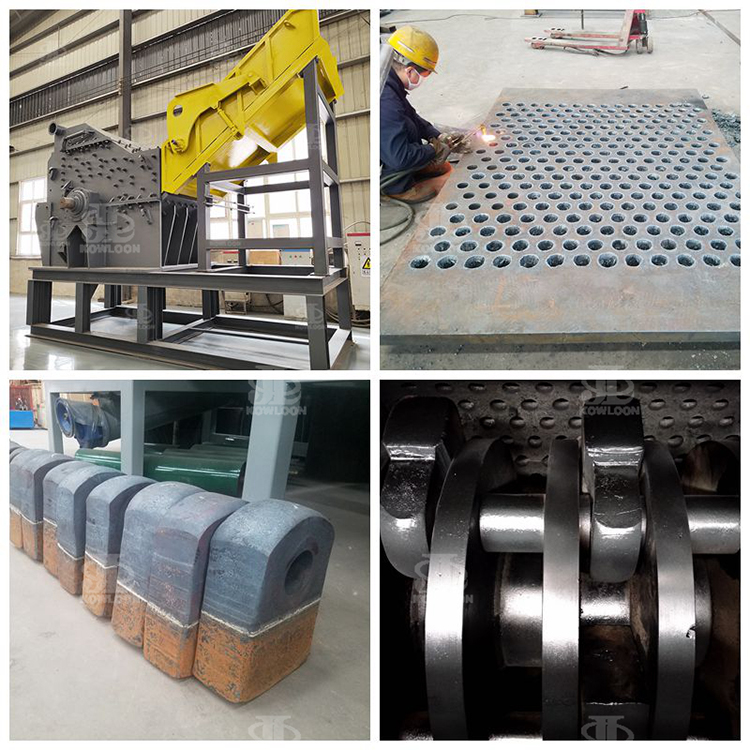

1. The motorcycle crusher blade is a meshing blade refined with high alloy, which has a good crushing effect on any high hardness material;

2. The motorcycle crusher is installed with a foundation, and the startup is stable without too much noise;

3. The motorcycle crusher uses an automatic operation cabinet, which has a high degree of automation and saves manpower;

4. The motorcycle crusher has a sturdy structure and densely clothed stiffening plates to ensure the strength of the box.

Technical Data

|

Model |

JLHC-200 |

JLHC-315—420HP |

JLHC-450—600HP |

|

Thickness of case plate |

30mm |

40mm |

50mm |

|

Thickness of screen |

60mm, material: cast steel, mesh 65*85mm |

100mm, material: cast steel, mesh 65*85mm |

100mm, material: cast steel, mesh 65*85mm |

|

Thickness of edge lining plate |

40mm |

50mm |

60mm |

|

Main shaft Diameter |

200mm,material:40Cr |

250mm,material:40cr |

280mm,material:40cr |

|

Rotor disc |

φ800mm, thickness 50mm, welding wear layer |

φ900mm, thickness 60mm, welding wear layer |

φ1200mm, thickness 80mm, welding wear layer |

|

Hammer |

10pcs, material: 13Cr2Mn, unit weight: 35KG |

10pcs, material: 13Cr2Mn, unit weight: 45KG |

14pcs, material: 13Cr2Mn, unit weight: 75KG |

|

Thickness of Forced feed plate |

16mm, hydraulic system |

20mm, hydraulic system |

20mm, hydraulic system |

|

Motor/control cabinet |

8P-200kw (1pcs), brand: WNM Soft starting cabinet, electrical components: Chint/Delixi |

8P-315kw (1pcs), brand: Simo - Slip Ring motorcyclo motor water resistance starting cabinet, electrical components: Chint/Delixi |

8P-450kw (1pcs), brand: Simo - Slip Ring motorcyclo motor water resistance starting cabinet, electrical components: Chint/Delixi |

|

Feed chain conveyor |

9000*1200mm,1pcs, power:7.5KW |

12000*1400mm,1pcs, power:11KW |

12000*1600mm,1pcs, power:11KW |

|

Vibrating discharge machine |

2500*1000mm,1pcs, power:3KW |

2500*1000mm,1pcs, power:3KW |

3000*1200mm,1pcs, power:4KW |

|

Discharge conveyor |

1000*6000mm,1pcs, power:4KW |

1000*6000mm,1pcs, power:4KW |

1000*6000mm,1pcs, power: 4KW |

|

Magnetic separation vibration feeder |

2000*1000mm,1pcs, power: 3KW |

2000*1200mm,1pcs, power: 4KW |

2000*1200mm,1pcs, power: 4KW |

|

Drum magnetic separator |

1000*650mm1pcs, power: 5.5KW |

800*1000mm 1pcs, power: 7.5KW |

1000*1000mm1pcs, power: 7.5KW |

|

output conveyor |

800*8000mm1pcs, power: 4kw |

800*8000mm1pcs, power: 4KW |

1000*8000mm1pcs, power: 5.5KW |

|

Slag removal conveyor |

500*8000mm1pcs, power: 3kw |

600*8000mm1pcs, power: 3KW |

650*8000mm1pcs, power: 4KW |

|

DMC-120 Filter bag type dust collector/Cyclone/pipe/fan |

1set power: 7.5KW |

1set power: 11KW |

1set power: 22KW |

|

Capacity |

4-6t/h |

8-10t/h |

10-15t/h |

Clients