Multi-Functional Drying Machine Industrial Rotary Air Dryer Machine Equipment

Applicable Materials:

Fertilizer, feed, sand, mineral powder, coal slime, river sand, slag, coal, dry powder mortar, desulfurization gypsum and other materials

Application Areas:

Material drying in cement, mining, building materials, chemical industry, compound fertilizer production and other industries

- Fitted Solution and Offer , 24 Hours Online.

- Oversea Installation , Training on Request .

- Continue provide Wearing Parts and Service !

Video

Description

Drying Equipment Multi-Functional

Application areas:

Material drying in cement, mining, building materials, chemical industry, compound fertilizer production and other industries

Applicable materials:

Fertilizer, feed, sand, mineral powder, coal slime, river sand, slag, coal, dry powder mortar, desulfurization gypsum and other materials

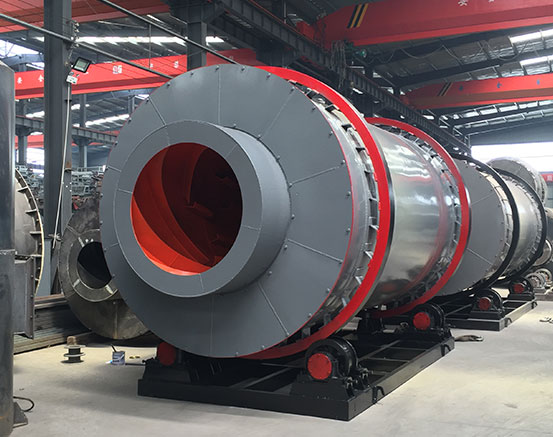

The dryer is also called a rotary dryer, which is widely used for material drying in cement, mining, building materials, chemical industry, compound fertilizer production and other industries. The thermometer can display the temperature change at the inlet and outlet of the dryer, which provides a basis for controlling the working temperature (generally 350-380 degrees) in the cylinder.

The dryer is generally suitable for granular materials, and can also be used for partially mixing materials to dry sticky paste materials or materials with high water content. Its advantages are large production capacity, wide application range, small flow resistance, large allowable fluctuation range in operation, and convenient operation. Commonly used for drying fertilizer, feed, sand, mineral powder, coal slime, river sand, slag, coal, dry powder mortar, desulfurization gypsum and other materials.

Process flow

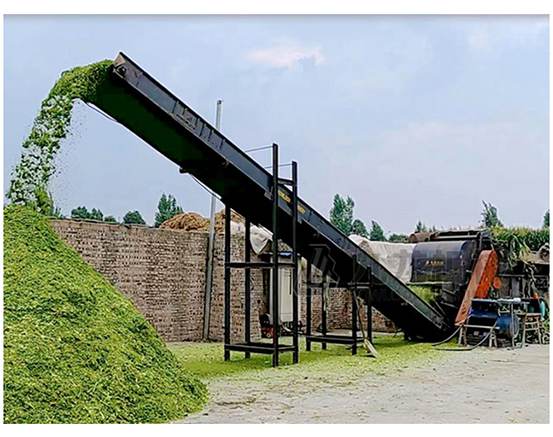

The dryer is mainly composed of a heat source, a feeding device, a belt feeder, a rotary drum, a belt discharger, an induced draft fan, a dust collector and a power distribution cabinet. The working principle of this set of equipment is as follows: because the material has a certain viscosity, the wet material is divided into the following working areas after entering the drying drum:

1. In the material guide area, the wet material mud enters this area and contacts with high temperature hot air to quickly evaporate the water. The material is moved by the large guide angle guide plate, and it will be introduced into the next work area if it does not form a bond;

2. The cleaning area is picked up. The wet material is picked up by the copy board to form a material curtain in this area. When the material falls, it is easy to form the phenomenon of sticking to the drum wall. In this area, because the equipment is designed with a cleaning device, the cleaning device is very reasonable. In the process, the cleaning device also plays a role in crushing the agglomeration of material balls, thereby increasing the heat exchange area and improving the drying rate;

3. In the inclined lifting plate area, the wet slime has been in a loose state with low moisture content in this area, and the material has no bonding phenomenon in this area. After sufficient heat exchange, the material reaches the required moisture state and enters the discharge area;

4. In the discharge area, the drum does not have a copy plate in this area, and the material rolls and slides to the discharge port in this area to complete the entire drying process.

Jiulong Machinery has four series of drying series, dehydrating series, heat source series and crushing series of products with high technological content. Coal drying series products are suitable for slime, raw coal, clean coal, washed coal and bituminous coal. The feed dryer is suitable for high-humidity materials such as distiller's grains, potato residue, starch residue, soybean residue, sauce residue, vinegar residue, yeast, pulp and so on. Industrial slag sludge treatment series products are suitable for sludge, slag, etc. The equipment has a large capacity and can be continuously produced. It is equipped with a variety of heat sources, multi-stage dust removal, and rotary drum drying supports customization, and can be equipped with a variety of heat sources.

Product advantages

The heat source of the dryer comes from the combustion device. The dryer adopts the downstream heating method. Therefore, the materials that need to be dried will slip into the cylinder from the feeding box and the feeding material, that is, they will be pushed back by the screw plate. The dryer is placed obliquely. On the one hand, the material flows to the rear end under the action of gravity and rotation. On the other hand, the material is repeatedly picked up by the copy board, brought to the upper end and then continuously scattered, so that the material forms a uniform curtain in the cylinder. It fully exchanges heat with the hot air in the cylinder. As the material is repeatedly scattered, the moisture contained in it is gradually dried, so as to achieve the purpose of drying. Jiulong dryer adopts reasonable operating parameters, coal consumption and electricity consumption are reduced by more than 10-15% compared with ordinary dryers, and output per unit is increased by more than 10-15%. It has been widely used in cement and mineral processing enterprises. The dryer is composed of an inclined and rotating long cylinder. The wet material enters from the upper part of the left end. During the downward movement in the cylinder, it contacts with the hot air in the cylinder or the heated cylinder wall to achieve the purpose of drying. Its main application Drying of various bulk materials.

Show results

1. Reliable operation: The dryer achieves "zero horizontal thrust", which greatly reduces the wear of the supporting roller, and the equipment runs stably and reliably.

2. Make full use of energy: the downstream drying method is adopted, hot air and materials enter the dryer from one side at the same time, and high temperature hot air can be used.

3. Energy saving/environmental protection: The dryer is fully sealed to reduce heat loss and dust emissions. At the same time, it is equipped with a multi-stage dust removal system to prevent and protect the environment again. It also provides users with a site that meets environmental standards.

4. Intelligent operation: The Plc intelligent centralized control system is easy to operate, and each equipment cooperates tacitly, which greatly improves the drying operation efficiency.

5. The structure is reasonable and the work is guaranteed: the new internal structure, feeding and discharging device strengthens the cleaning and heat conduction of the dispersed materials, solves the adhesion phenomenon of the inner wall of the cylinder, and avoids feeding blockage and discontinuity. The phenomenon of unevenness and reverse material reduces the load of the dust removal system.

Application field

1. For customers in areas where coal-burning is allowed: optional coal-fired dryer production line;

2. For customers with natural gas, gas and other resources: gas-fired slime drying equipment can be used;

3. For customers with steam resources: the production line of steam drying slime equipment can be used.

Technical Data

Clients