How to deal with solid waste in paper mills?

Paper mill waste alternative fuel treatment system helps you

The total amount of wastewater discharge and COD emission from the papermaking industry ranks first among all types of industries in my country. It is precisely because of this that pollution control in the paper industry is the primary issue in our country. In the pulp and paper production process, various solid wastes (i.e. waste residues) are produced in large quantities and are highly concentrated. If they are not disposed of properly and are discharged arbitrarily, they can also endanger the human environment.

These paper mill wastes include waste ropes (including plastic, a large amount of metal wires, bags, etc.) and woven waste (because metal wires are wrapped around plastic films, cloth, like woven fabrics), etc. The main components of paper mill waste are plastic, steel wire and residual pulp. Some of these materials mix and tangle together to form large objects that are difficult to separate. Paper mill waste emissions are measured in hundreds of tons each year. Impurities include some plastics and other inorganic substances that cannot be recovered from waste plastics, including sediments and scum produced by flocculation in sewage treatment systems, sludge produced by sewage treatment systems, and some domestic garbage produced in living areas.

Waste treatment typically involves converting waste into energy before feeding it into specialized waste-to-energy plants. The other sorts the waste and then converts it into a form of fuel suitable for use in conventional power plants and industrial uses.

China is a major manufacturing country and produces a large amount of waste. Under various pressures, China’s alternative fuel market is ushering in a blue ocean. At present, many policies advocate enterprises to develop in the direction of alternative fuels.

SRF is the abbreviation of Solid Recover Fuel. SRF is usually refined RDF. SRF is not garbage, but a clean, homogeneous, high-quality, high calorific value fuel that can be used in power plants or cement plants to replace traditional Fossil fuels such as coal, etc. Moreover, SRF is a very environmentally friendly fuel, its carbon dioxide emissions are only one-quarter of coal, and NOX emissions are also significantly reduced.

Paper mill alternative fuel SRF

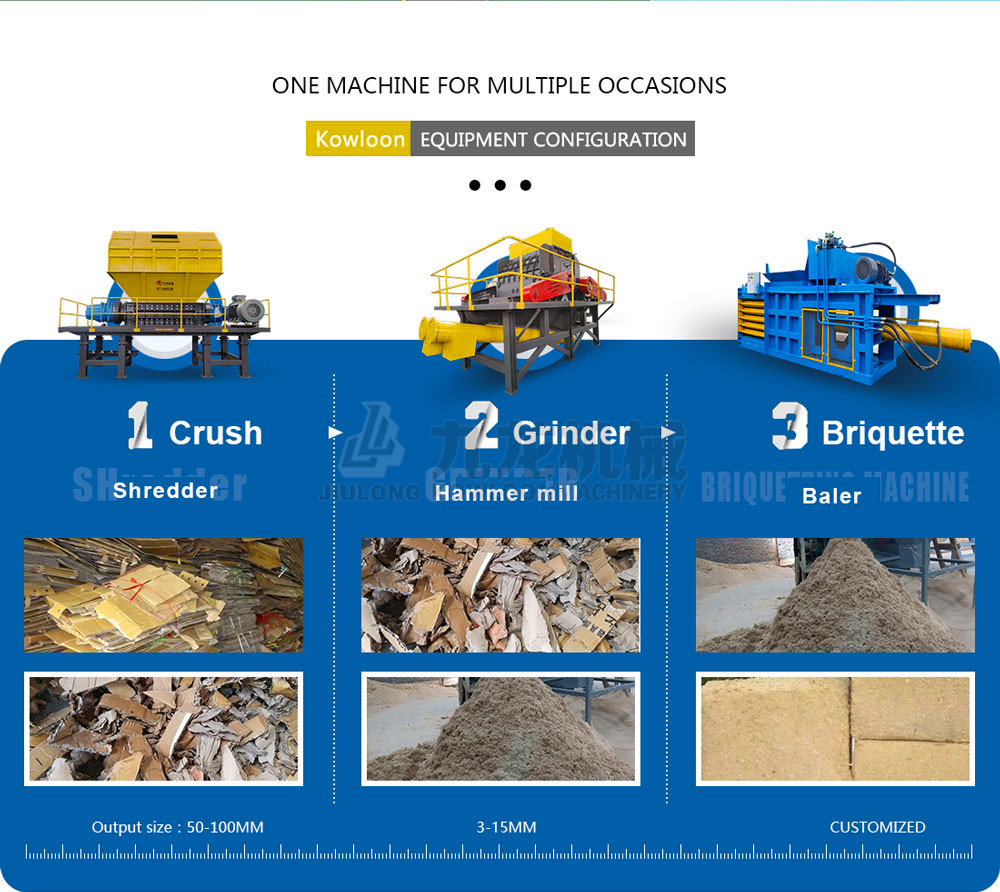

There are many types of solid waste in paper mills. Kowloon Environmental Protection treats various components of solid waste and performs SRF preparation procedures according to different material properties, realizing the resource utilization of solid waste in paper mills.

The papermaking waste SRF coal-fired coupled power generation and the use of a large proportion of coal-fired fuels can save power plant companies a lot of coal-fired fuel costs, while also ensuring the safety, stability, and continuous operation of the power generation, and the emissions are fully up to standard.

Paper mill waste alternative fuel treatment system: Paper mill waste first enters the coarse crusher for coarse crushing (≤20cm), and then passes through magnetic separation, butterfly screen, drum screen, bounce screen, air separator and other sorting equipment to separate incombustibles and combustibles After separation, the combustible materials enter the fine crusher for secondary crushing (≤2cm). The crushed materials enter the dryer to reduce the moisture to less than 10%. The dried combustible materials enter the high-pressure molding machine for compression molding.

Paper mill waste alternative fuel treatment system

The SRF/RDF alternative fuel industry is like a venous system of modern industrial civilization, which fully purifies the arterial blood on which human social civilization depends. This is a sustainable and circular development track. SRF/RDF is equivalent to the “green coal” of the new century. It is foreseeable that in the near future, it will become the fourth largest energy product after coal, oil, and natural gas, and It is an inexhaustible green energy product.