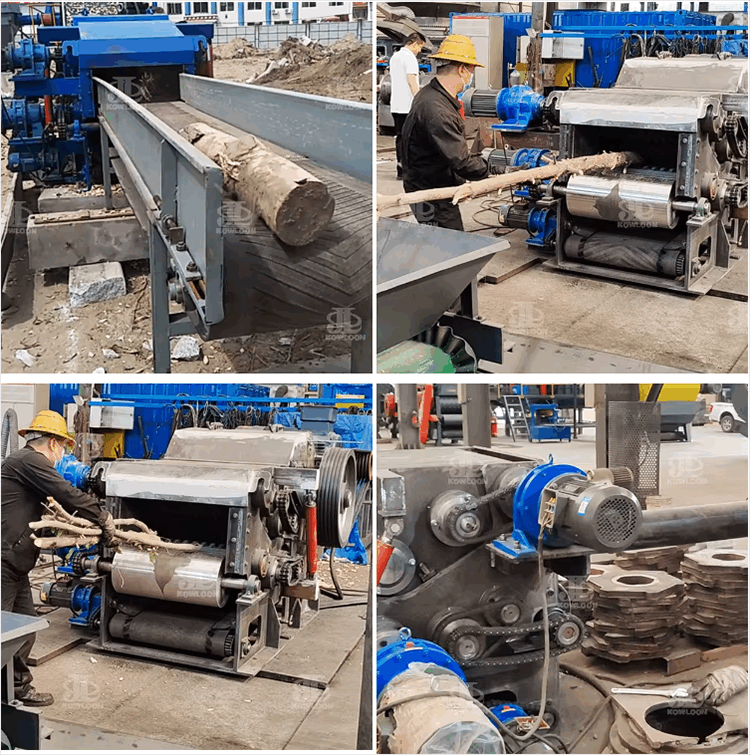

Drum Wood Chipper Machine for Crushing Wood Log Branch Barks Bamboo

Application Materials:

Drum chipper is a special equipment for producing wood chips. It can work with all kinds of wood materials such as wood logs, tree branches, wood slab, twigs, planks, bamboo, veneer, tree stump, waste wood, etc.

Power: 45KW-250KW

Working Capacity :3-30 t/h

- Fitted Solution and Offer , 24 Hours Online.

- Oversea Installation , Training on Request .

- Continue provide Wearing Parts and Service !

Video

Description

Drum chipper is a special equipment for producing wood chips. It can work with all kinds of wood materials such as wood logs, tree branches, wood slab, twigs, planks, bamboo, veneer, tree stump, waste wood, etc.

Drum chipper features

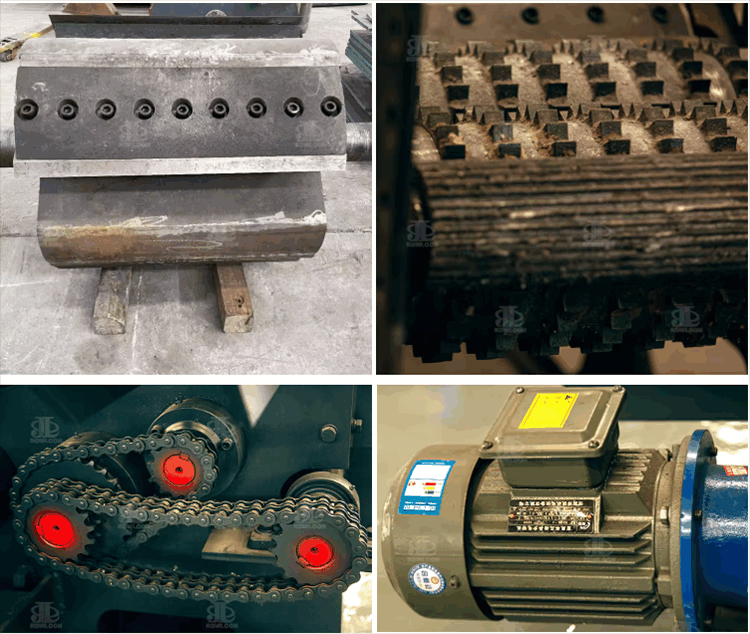

The structure of drum chipper: knife rotor, feeding rollers, feed and discharge conveyors, hydraulic system and other parts. The body of drum chipper made of high strengthen steel, the moving knives on rotor could be 2 knives, 3 knives, 4knives. The moving knife fixed by high strength bolts and press board; hydraulic system helps chipper has ability to process different diameter materials .

Brand Name :Kowloon Machinery

Condition :New

Voltage :220V/380V

Power :200 kw

Model :JLBX216/JLBX218

Product name :Wood Drum Chipper

Application :wood processing plant

Usage :Biomass fuel or other uses

Raw material :Whole Tree/branches/straw

Main Motor :45 kw - 250 kw

Moving blade :3 blades

Capacity :3-30 t/h

Weight :7000kg

Dimension :2200*2150*1500mm

Feature

The structure of drum chipper: knife rotor, feeding rollers, feed and discharge conveyors, hydraulic system and other parts. The body of drum chipper made of high strengthen steel, the moving knives on rotor could be 2 knives, 3 knives, 4knives. The moving knife fixed by high strength bolts and press board; hydraulic system helps chipper has ability to process different diameter materials .

Appliance

JLBX drum wood chipper application: logs, branches, veneers, waste veneers, bamboo, cotton stem and other non wood fiber stems. These raw materials can be cut into wood chips of different specifications at one time, these chips can be used as the basic raw material for making particleboard, fiberboard, non wood-based board and pulping and papermaking .

Delivery &Shipping for drum chipper

1. Plastic wraps to protect wood shredder, tire shredder from dust, moisture and corrosion.

2. Wooden case for compact machine or wearing parts as the outside package. Or according to the customer requirements.

3. Excellant logistic team to guarantee the shredder machines to be safely shipped to customer warehouse, no extra fee on export or import on custom.

Kowloon Service

1. Pre-sales: Provide fitted solution and offer to customers, is able to adjust the layout of complete line to fit customers working area, also provide technical support 24 hours service online.

2. After sales:Kowloon skilled technicians are experienced at oversea installation, therefore they are available to assist with onsite installation, commissioning & training on request. Layout drawing, circuit diagram and maintenance manual will be provided together with our products after sales, so that ensure customers have plenty of time to get prepared for installation.

3. Wearing parts support:Kowloon has widely built extensive cooperation with wearing parts partner manufacturers more than 18 years, has ability to continuously provide wearing parts and after-sale service to global market.

Company Introduction

Kowloon Machinery located in industrial hub of Zhengzhou city, China, design and manufacture industrial shredder, wood processing machinery, waste tire recycle equipment and scrap metal recycling machines. Kowloon products approved by CE and ISO certificates. Up to now, we have exported to more than 30 countries and share markets in worldwide, and now are still growing continuously.

We effort on improving and researching, in past years, various of new products were developed and becomes popular in domestic and abroad market, won good reputation and corporate image, we always effort on best quality and service, welcome to inquiry!

Technical Data

|

Model

|

JLBX216

|

JLBX218

|

|

Infeed size (H*W)

|

230x590mm

|

300x680mm

|

|

Process range

|

≤φ230mm

|

≤φ300mm

|

|

Moving blade

|

2/3/4 blades

|

2/3/4 blades

|

|

Rotary speed

|

590 rpm

|

650 rpm

|

|

Main motor

|

55kw

|

90-110kw

|

|

Feeder motor

|

4kw+4kw

|

5.5kw+5.5kw

|

|

Hydraulic motor

|

1.5kw

|

1.5kw

|

|

Feeding conveyor motor

|

3kw

|

4kw

|

|

Weight

|

5030kg

|

7000kg

|

|

Dimensions

|

1800*1900*1210mm

|

2200*2150*1500mm

|

Clients