Cardboard Box Shredder Paper and Carton Recycling Machine Customized Powerful

Product name :Paper Shredding Machine

Voltage :220/380V/Customize

Raw material :Old Corrugated Paper, Cardboard

Finished Products :Paper Block

Motor :11kw -90kw

Rotor rotary speed :8-18 rpm

Production Capacity :5-20 t/h

- Fitted Solution and Offer , 24 Hours Online.

- Oversea Installation , Training on Request .

- Continue provide Wearing Parts and Service !

Video

Description

Customized Powerful Cardboard Box Shredder Paper and Carton Recycling Machine

Eco-friendly Cardboard Shredder Industrial Carton Recycling Machine

Factory Supply CE ISO Carton Crusher Cardboard Box Shredder for Packaging Materials

Double Shaft Cardboard Shredder Cardboard Recycling Machine

Waste paper recycling is a process of repeated papermaking, mainly recycling paper fibers in waste paper, which can greatly save resources and reduce pollutant emissions. In foreign countries, waste paper has the reputation of urban forest resources. Whether it is waste newspapers, book paper, office paper, or kraft paper, cardboard boxes, corrugated paper, etc., they are all valuable fiber raw materials used in papermaking. Using waste paper to make paper has the advantages of low energy consumption, low processing cost, low unit raw material cost, and reduced environmental pollution. Therefore, paper and cardboard produced from recycled fibers are called green products.

The waste cardboard shredder is a special equipment for waste paper and waste board. The unique design idea and processing technology of the waste paper shredder can make any shape of waste corrugated paper, cardboard, newspapers, waste books, cartons, paper tubes, paper tubes, cardboards. Wait for the material to be quickly processed into small pieces and collected to ensure that there is no dust.

Condition :New

Product Type :Paper Recycling Machine

Processing Type :Waste Paper

Place of Origin :Henan

Weight :18000

Warranty :1 Year

Machinery Test Report :Provided

Video outgoing-inspection :Provided

Warranty of core components :1 Year

Core Components :PLC, Motor, Pump, Bearing, Gearbox

Brand Name :Kowloon Machinery

Voltage :220/380V/Customize

Product name :Paper Shredding Machine

Finished Products :Paper Block

Raw material :Old Corrugated Paper, Cardboard

Application :Packing Industry/Paper Mill

Model :JLSS1000/JLSS1200/JLSS1500/JLSS2000

Motor :11kw -90kw

Gearbox :2units,planetary type, gear transmission

Weight :6000kg - 29000kg

Lubrication system :With automatic oil lubricator

Rotor rotary speed :8-18 rpm

Production Capacity :5-20 t/h

Applicable Industries :Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Food & Beverage Shops.

Showroom Location :Egypt, Italy, Germany, Viet Nam, Philippines, Brazil, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Morocco, Argentina, South Korea, Sri Lanka, Romania, Bangladesh, Kazakhstan, Ukraine, Tajikistan, Malaysia, Australia

Packaging and delivery

Selling Units :Single item

Single package size :100X100X100 cm

Single gross weight :1000.000 kg

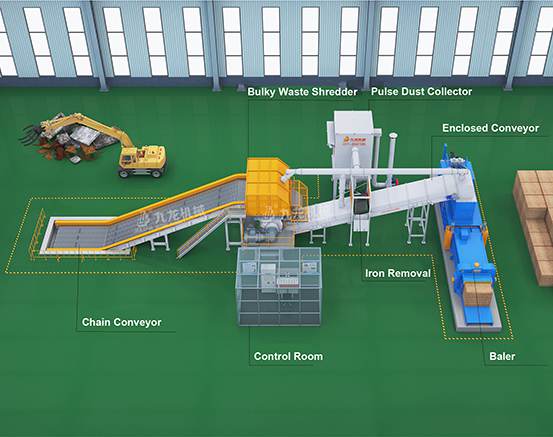

Automatic 1-4 TPH Packaging Carton Cardboard Box Shredder AOCC Paper Dry Pulping Line

High Capacity Cardboard Recycling Machine

The production of paper products regularly produces a lot of waste. The production waste or production surplus, for example in the form of paper bales, paper cuttings, paper rolls or paper sheets, presents many companies with logistical challenges. Industrial paper shredders reduce large volumes economically. The shredded pieces can be reintegrated into production processes after being re-pulped.

Kowloon Machinery industrial paper shredders make a great contribution to the economical shredding of paper and corrugated cardboard. Strong, robust drives and rotors specifically designed for shredding paper or cardboard also make it possible to process material that is difficult to shred. Our machines can handle all throughput requirements for post-consumer applications such as waste paper, cartons, files and documents, shipping packaging, and industrial production waste. This includes cardboard tubes, paper webs, paper rolls, edge trims, printing waste or paper bales.

Cardboard Shredder Features

1. Low speed, high torque rotor, cutting and shearing working principle suitable for both soft and hard materials;

2. Blades made of special alloy, different shape, thickness and cutting head quantity providing the optimum solution for different materials.

3. Siemens, abb, weg…etc quality motors are available for different customers’ options

4. Schneider, chint, siements…etc electrical components to ensure steady performance and realize machine 24hours running, also plc system is optional to enabling automatic reverse for overload protection and minimizing blades damages;

5. Individual electrical control panel with plc control system ensure the machine work properly and safety;

6. Detachable type cutting head on shredder blades, makes the maintenance and replacement of wearing parts easier and much shorten maintenance time.

7. Low speed, lower noise, workable in workshop and outdoor.

If you are interested in our production line, please do not hesitate to contact us and we will provide you with a tailor-made solution.

Technical Data

|

Model

|

JLSS1000

|

JLSS1200

|

JLSS1500

|

JLSS2000

|

|

Motor

|

15kw+15kw

|

22kw+22kw

|

55kw+55kw

|

90kw+90kw

|

|

Gearbox

|

2units,planetary type, gear transmission

|

|||

|

Shaft

|

solid shaft, made of 40Cr, hardened and tempered

|

|||

|

Shredder chamber (inner)

|

940x725mm

|

1120x1000mm

|

1450x1100mm

|

1920x1250mm

|

|

Rotor rotary speed

|

8-18rpm

|

8-18rpm

|

8-18rpm

|

8-18rpm

|

|

Blade

|

diameter 360mm

|

diameter 360mm

|

diameter 530mm

|

diameter 560mm

|

|

Lubrication system

|

With automatic oil lubricator

|

|||

|

Dimension

|

3.2x1.3x2.3m

|

3.2x2x1.9m

|

4.9x2.8x2.8m

|

6x3.8x4.8m

|

|

Weight

|

6000kg

|

12000kg

|

18000kg

|

29000kg

|

Clients